Welcome to karoon khozestan co

- Group:

- Type:

- Brand:

Steel Bucket Elevator Belts

Steel Buckets Elevator Belts

Kauflex is a conveyor belt made from a steel mesh with transversal rigidity, manufactured for metallic elevators where high traction resistance is required and low levels of belt stretching.The minimum cover used for this type of belt is 3 + 3 mm. The construction of the Kauflex belt means that it may be used with relatively small diameter drums and long length elevators.

The most important characteristics of the metallic meshes used are:

- Maximum elongation of 0.3% at full working load, even for the longest belts.

- Greater resistance to wear and tear of the buckets due to the staggered formation of the double weft plies on each face, thus ensuring that the belt is not torn by the crews.

- Possibility of constructing the mesh with “free areas” (the standard construction of the mesh does not include free areas).

- Belts for metallic elevators are used in: power stations, fertilizer plants, smelting works, cement plants, silage grain elevators and harbour

elevators.

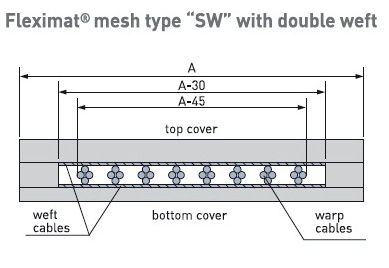

- The Kauflex belt for metallic elevators is constructed from Fleximat® mesh with a rigid weft. The cables used in the warp direction along with the weft direction cables form a compact mesh with a structure which is resistant to deformation and offers excellent resistance to potential damage. The open construction of the cables allows high-adherence rubber to penetrate the structure, thus avoiding the potential corrosion of the cables in the case of accident and guaranteeing its operation in an excellent state of repair.

The cables of the structure offer the following advantages: improved behaviour under compression; reduced stretching; excellent penetration of the rubber protective layer; and high levels of resistance to external forces.The high elasticity weft cables act as a barrier against wear and tear and increase the adherence of the screws to the buckets. They also offer increased transversal rigidity, which in turn results in improved operation.

The joints for this type of belt may be realised in a series of different ways:

- Joints using staples. We recommend that specially resistant joints be used for this type of belt, made from high resistance aluminium. Kauman supplies these types of joints in accordance with the width of the belt and the working stress for the belt.

- Vulcanisation. In this case the guidelines established by our Technical Department must be followed to the letter and the materials provided must be used.

For more information and buy equipments , kindly contact sales department.